Artists and engineers appreciate the relief brought about by CAD drawing, modeling and software. Years back, it took a lot of skill to produce accurate designs and much diligence in the whole process. A single error was disastrous for companies and cost a lot in time and money.

All these are now in the past, as CAD has opened up the possibilities for manufacturers all over and it has further evolved allowing even novices to produce simple designs on their personal computers. It allows for precision and accuracy in designs and saves companies in millions in testing out the viability and success of a new product. Here are some of the numerous benefits that engineers enjoy today:

1. Eliminate scaling and go full size

Drawing on paper requires an individual to use scale dimensions in the design. The problem with scaling is that it at times presented problems with proportionality. Designs of less complex things like buildings do not present much problem but with complex machines and robots, using full size is probably the best way to design and get a clear view of all features from scratch.

2. Centralization of tools

The computer software gives an individual all the tools they need, which are accessible with the click of the mouse. Although one needs some level of training to use CAD software effectively, once the skill has been gained they make work far much easier and a design which through drawing would have taken weeks to fully complete happens in a matter of days. The challenge in using the software is made completely worth it by the successful results.

3. Absolute and complete accuracy

Human is to err and the same applies when drawing designs or making prototypes. The computer software eliminates this percentage of error. Some CAD programs are highly advanced and even when one makes an error in input or expression of design, the software readily adjusts the error to what is appropriate.

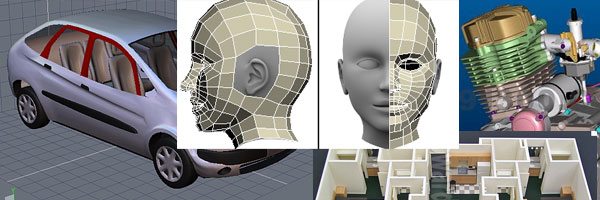

4. 2D and 3D designs

CAD enables one to see designs and images in both 2D and 3D. Whereas 2D is great for the design, 3D is what one needs to visualize properly the output of the design. The virtualization of a design to view it almost as one would the real thing enables prevention of many errors, enhances production of a more accurate design and eliminates the production of numerous prototypes to see how it would be in real life.

5. Efficient storage

Before the completion of any design as the accurate and final copy to be used to manufacture, an engineer would have to draw many drafts in order to get the final one. Drafting is a tedious process of finding errors and improvements and drawing a design from scratch just to add a minimal adjustment. With the software all, these adjustments are simple to make and occur in one file.

Furthermore, since one has to keep the drafts unlike placing them in a huge folder, you simply save the new designs in the computer, which has more and less bulky storage options. Making copies of the design is simple.

6. Replication of ideas

A great benefit of cad is that you can use parts of a design from a previous project and replicate them to another. This saves valuable time when making improvements of a manufactured project or when creating a series of productions. For instance if creating a robot and upon launch it turns out to be successful you can use the design of the original to replicate the robot series with ease creating similar and unique features for each.

7. No loss of work

It is not only irritating but one loses a lot of money in the event that a design drawn is lost or damaged. With the Cad, you simply store your information in various locations and make back up files. The chances of losing data are minimal and even when it occurs, data can be recovered.

8. Reduction in production costs (determine viability beforehand and less prototypes)

Manufacturing companies used to lose a lot of money in creating prototypes before launching a machine or project. With CAD however, one does not have to create a prototype to test the viability of a design. You need only to produce a prototype in the final stages.

About the author: Adam Clifford is a technology expert and shares his tech tips through guest posts. He works with a company that manufactures touch screen kiosks for business purpose.